PUI | Global Corporate HQ

15311 Barranca Parkway

Irvine , CA , 92618

United States

Phone:(714) 544-2700

Email: sales@gopui.com

15311 Barranca Parkway

Irvine , CA , 92618

United States

Phone:(714) 544-2700

Email: sales@gopui.com

| Items |

AS04504PS-X-R eXtreme Series 170 Hertz (Hz) Resonant Frequency Speaker List Price {QUOTE}

|

AS06504PS-X-R eXtreme Series 130 Hertz (Hz) Resonant Frequency Speaker List Price {QUOTE}

|

||

| Manufacturer Stock | N/A {0} | N/A {0} | ||

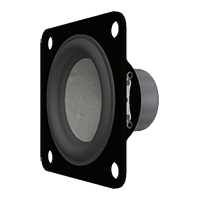

| Description | N/A PUI Audio™'s eXtreme Series speakers are purpose-built for superior performance using Klippel-optimized motor designs. Forced-air vented voice coils combine with a high-grade neodymium motor for extreme power handling, extremely flat frequency response, and a surprising amount of bass when used with tuned-port or passive radiator assisted enclosures. | |||

| Brands | N/A PUI Audio™ | |||

| Manufacturer | N/A PUI Audio�, Inc. | |||

| Rated Input Power | N/A 10 W | |||

| Maximum Input Power | N/A 20 W | |||

| Impedance | N/A 4 Ω | |||

| Impedance Tolerance (±) | N/A 15 % | |||

| Sound Pressure Level (SPL) | N/A 86 dB | N/A 88 dB | ||

| Sound Pressure Level (SPL) Tolerance (±) | N/A 3 dB | |||

| Testing Condition for Sound Pressure Level (SPL) | N/A At 1 W/0.5 m (Average 0.8, 1.0, 1.2, 1.5 kHz) | |||

| Resonant Frequency | N/A 170 Hz | N/A 130 Hz | ||

| Resonant Frequency Tolerance (±) | N/A 20 % | |||

| Frequency Range (-10 dB) | N/A 90 ~ 20000 Hz | N/A 80 ~ 20000 Hz | ||

| Frame Material | N/A Stamped Steel | |||

| Magnet Material | N/A Neodymium (NdFeB) | |||

| Weight | N/A 63 g | N/A 92 g | ||

| Ingress Protection Rating | N/A Ingress Protection (IP65) | N/A Ingress Protection (IP65) with Water Resistance (WR) Coating | ||

| Recommended Sealed Enclosure Volume Range1 | N/A 0.05 ~ 0.40 L | N/A 0.06 ~ 0.60 L | ||

| Recommended Vented Enclosure Volume2 | N/A 0.40 L | N/A 0.60 L | ||

| Vent Diameter | N/A 20 mm | N/A 26 mm | ||

| Vent Length | N/A 244 mm | N/A 350 mm | ||

| Tuning Frequency | N/A 100 Hz | N/A 88 Hz | ||

| Acceptable Soldering Methods | N/A Hand Solder | |||

| Buzz, Rattle, etc. | N/A Should not be Audible with 6.32 V Sine Wave from 90 Hz to 20 kHz | |||

| Environmental Compliances | N/A Registration, Evaluation, Authorization and Restriction of Chemicals (REACH 197) Restriction of Hazardous Substances (RoHS) 2015/863/EU | |||

| Polarity | N/A Cone Shall Move Forward when a Positive Voltage is Applied to the Positive Terminal | |||

| Operating Temperature | N/A -25 ~ +60 ºC | |||

| High Temperature Test | N/A 96 hours at +60°C ± 2°C followed by three hours in normal room temperature | |||

| Low Temperature Test | N/A 96 hours at -20°C ± 3°C followed by three hours in normal room temperature | |||

| Humidity Test | N/A 96 hours at +40°C ± 2°C with relative humidity between 90% and 95% followed by 6 hours in normal room temperature | |||

| Vibration Test | N/A Frequency 30±15 Hz, Amplitude 1.5 mm for 3 Hours. After test, SPL shall not deviate by ±3 dB from pre-test measurement | |||

| Drop Test | N/A 75 cm free falling on concrete floor, 10 times. | |||

| Load Test | N/A Speaker should not fail after applying 20 Hz ~ 20 kHz pink noise with HPF rated power input (RMS), 96 hours. | |||

| Note for Reliability Testing | N/A After each test, SPL shall not deviate by more than ±3 dB from pre-test measurement. | |||

| Features |

N/A

|

N/A

|

||

| Note |

N/A

Specifications subject to change or withdrawal without notice. Recommended speaker baffle opening is 41 mm. Always test-fit prior to closing mechanical design. Please maintain at least 6mm distance between top of frame and next surface. |

N/A

Specifications subject to change or withdrawal without notice. Recommended speaker baffle opening is 53.6 mm. Always test-fit prior to closing mechanical design. Please maintain at least 7 mm distance between top of frame and next surface. |

||

|

||||